ROGATOR® LIQUID

ROGATOR® LIQUID

Highlights

- Ready to spray in just 45 seconds with LiquidLogic’s fast and easy priming

- Triple cab filtration system provides first-class safety

- AWD SmartDriveTM technology for automatic and continuous wheel control

- Intuitive and comprehensive machine control with AccuTerminal®

Overview

RoGator Self-Propelled Sprayers

Don’t spray harder—spray smarter with RoGator’s liquid application system. Featuring LiquidLogic®, AWD SmartDriveTM and GatorTrakTM technology, it’s specifically designed to give you full control to deliver a more precise, efficient and effective application every time. Only on a RoGator.

Features

LiquidLogic®

Save valuable inputs, time and money

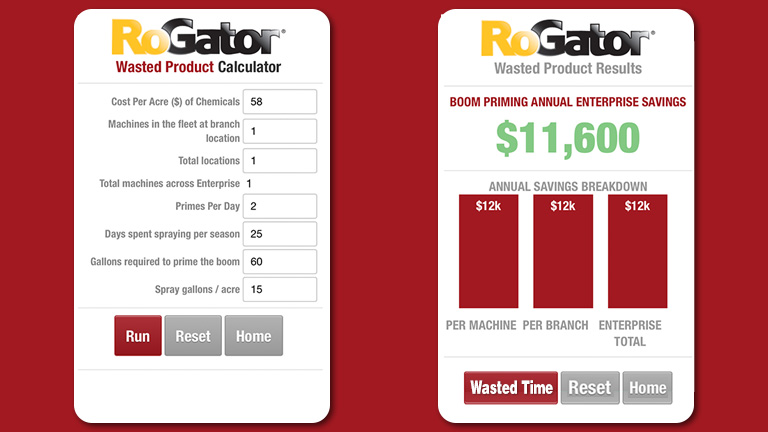

Unlike conventional spray systems, LiquidLogic® recirculation primes the boom in 45 seconds flat—saving you $232 per prime. And that’s not the only benefit.

Savings Per Season

Purdue University’s agronomy department released estimates that chemical costs for corn are around $58 per acre. With about 4 acres of wasted product every time a prime is performed, this amounts to $11,600 of wasted product per season when priming two times per day.

Purdue University’s agronomy department released estimates that chemical costs for corn are around $58 per acre. With about 4 acres of wasted product every time a prime is performed, this amounts to $11,600 of wasted product per season when priming two times per day.

E-Stop™ Control

Control up to 36 boom sections using e-stops and reduce overlap and wasted product while eliminating damage to management zones by utilizing durable electronic ball valves for instantaneous on/off section spray control.

OptiMotion™ Auto-Agitation

Automatically adjusts as the tank volume changes, freeing you to focus on application or refill rather than valve adjustments.

Boom Clean Out

Available on RoGator for 21 years, system effectively pushes product out of the boom plumbing to ensure clean lines and reduce contamination and crop damage—saving you up to $2,500 per spraying season.

OptiLoad™ Reload System

Transforms time-consuming rinsing procedures into a simple task accomplished inside the cab and at the reload station to ensure that every area of the machine is rinsed. RoGator’s reload area uses sweeping elbows and “Y” fittings in place of hard 90° and “T” fittings, reducing product build up. The continuous recirculating boom plumbing eliminates dead-end spots in which chemicals can get trapped and removes the need to pull end caps. A recent Purdue study determined that the FlowLogic recirculation boom plumbing can be rinsed to effectively remove water-soluble contaminants by 99.6% or greater with a triple rinse.

ClearFlow™ Product Recovery System

Manage rain, wind and other conditions by flushing unused product from the plumbing back into the tank prior to rinsing, where it can be re-agitated or off-loaded, minimizing waste and contamination.

Direct Injection

Whether using it for adjuvants or chemicals, this system allows you to inject variable-rate product into the system before the booms, all while reducing your risk of cleanout contamination. The system leverages a dual high-volume pump (5-200 oz. per min pump) with dual 40-gallon tanks mounted on opposite sides to keep the machine balanced with ground fill and rinse at the reload area.

Eliminate Waste

Exclusive FlowLogicTM technology maintains circulation and provides immediate flow throughout the boom, eliminating clogging, settling, and wasteful stationary spraying while always maintaining an optimal mixture.

Booms

A boom for every operator

Whether you’re trying to apply the highest volume possible, broadcasting over solid seeded crops or applying between rows, RoGator® has the boom for you.

Steel Booms: 90-, 100- and 120-ft. lengths with 10-, 15- and 20-in. nozzle spacing available.

Optional Aluminum Boom: 132-ft. length, and 5% lighter than steel for improved efficiency, less compaction, and nozzle and plumbing protection contained inside the A-frame structure.

Accessory kits

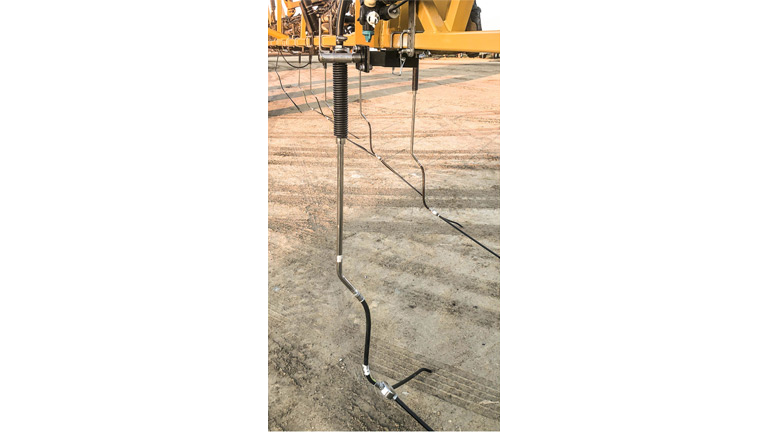

EZ Drops

Crop-guided, lightweight system for late-season nitrogen applications delivering nutrients on target to the base of the plant. Heavy-duty stainless steel breakaway springs and high-wear tips ensure durability, and the system can be folded from the cab for more convenience.

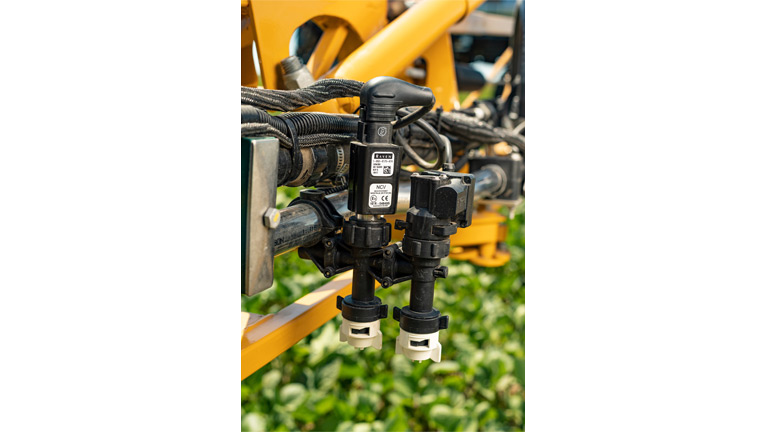

Hawkeye® Nozzle Control

A pressure-based system for precise application available through parts. Pair this with the E-Stop Control system to increase the system’s flow capabilities to open up a wide rate range. Various modes that increase the versatility of the system include:

- Bypass – NCV is disabled, flows through the E-Stop

- Standard – Hawkeye will control target flow rate and pressure

- On/Off – NCV will be 100% open or closed

- Variable Pressure (VP) – Will control to target flow rate and duty cycle by varying pressure

- High Flow – Simultaneously uses both the NCV and an E-Stop to achieve higher flow rates

- Tiered Nozzle – Hawkeye System (A) will operate in an On/Off mode in addition to controlling the E-Stop (B). This mode enables the following combinations: (A), (B), and (A)+(B)

Cab

Control has never been so comfortable

Every inch of the RoGator® cab has been designed to maximize your riding experience—and your efficiency.

- Ergonomic armrest for more comfort and control, and easier access to sprayer controls.

- Flat-folding booms for unmatched visibility on the road.

- Six-post cab design provides a clear view to the boom tip, regardless of length.

- Triple filtration system includes a prefilter and a charcoal cab filter to keep your environment virtually dust-, chemical- and odor-free.

- Recirculation filter keeps cab air clean, and a pressurizing fan maintains positive interior air pressure so unfiltered air can’t get in.

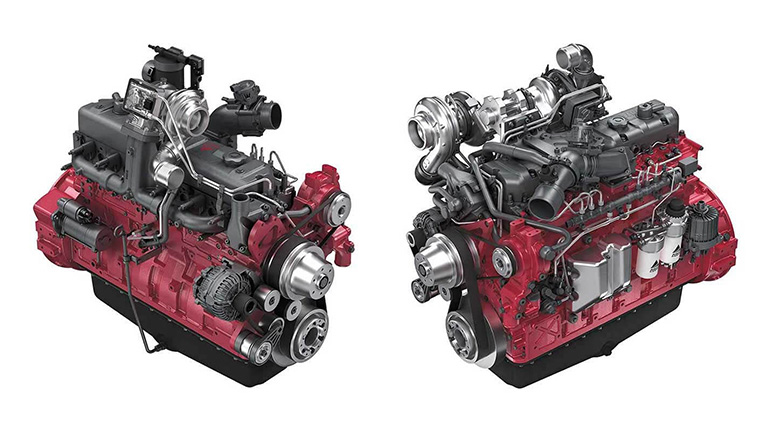

Engine

Power meets performance

The horsepower, torque and fuel economy to handle any terrain with ease—all while meeting emission compliance regulations.

- RG1100C/1300C: AGCO’s selective catalytic reduction (SCR) emissions technology in combination with cooled exhaust gas recirculation (cEGR) achieves Tier IV Final (T4F) emission regulation on the AGCO Power 84 AWF engines.

- RG900C: Uses the 74 AWF AGCO PowerTM engine and will only utilize the SCR system to meet emissions standards, ensuring increased power density and total fluid economy with an efficient after-treatment of exhaust gases.

| Model | Engine | Rated Horsepower | Peak Horsepower | Peak Torque | Emissions Control |

|---|---|---|---|---|---|

| RG900C | 7.4L | 280 | 302 | 885 ft-lbs | SCR |

| RG1100C | 8.4L | 315 | 341 | 1106 ft-lbs | SCR, CEGR |

| RG1300C | 8.4L | 339 | 370 | 1180 ft-lbs | SCR, CEGR |

Smartdrive

Better traction, better results

Ride confidently with SmartDriveTM technology, featuring continuous and independent control of each wheel for maximum traction. It automatically sends more power to the gripping wheel and ensures it gets the torque it needs, all while managing the slipping wheels—without any user input.

- Tractor Management System (TMS): Automatically increases engine RPM when more power is needed and reduces RPM when it’s not to reduce fuel consumption and noise in the cab.

- AccuCruiseTM and Shuttle Speed Control: Enables multiple speed settings at the touch of a button, allowing you to focus on more critical applications.

- Advanced Anti-Locking Brake System (ABS): Prevents skids and lock-ups for more controlled stopping in emergency situations.

- Turn Compensated Wheel Speed: Provides independent control of each wheel, driving the outside wheels faster to assist in tight turns and reducing soil disruption and crop damage.

- Optional Hill Climb Package: Increases power to the ground for efficient handling of steep and rugged terrain on the RG1300C.

- Parallel C-Channel Flex Frame: Pioneered by RoGator in 1993, this state-of-the-art frame keeps all four wheels on the ground—even when one wheel is lifted as high as 40 in.—maintaining solid contact with the ground and keeping the machine moving regardless of conditions, all with a smooth ride.

Gatortrack

Fewer tracks, more benefits

Leaving only two tracks behind, the optional GatorTrakTM 4-wheel steering system gives you everything you need to make any maneuver you want.

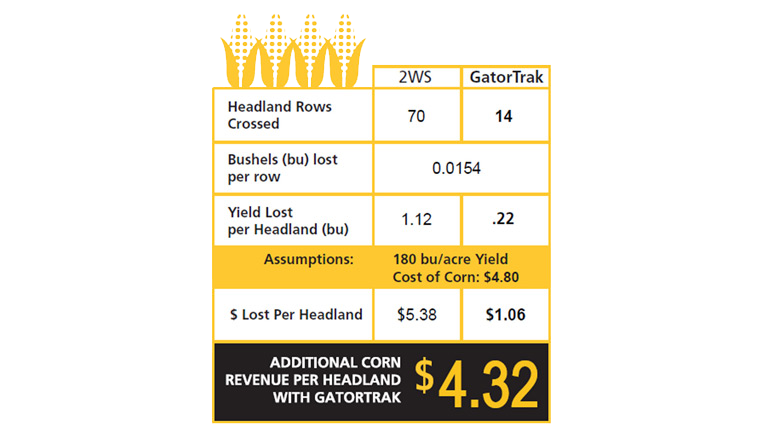

768x432.png)

Capabilities: Drive in a standard position with 2WS or minimize turn radius with either the 4WS or 4WS Auto. Use Crab steering to avoid field obstacles while maintaining precise even coverage.

Reduce Compaction: Initial tire paths compact soil by 80%, making it essential to reuse them whenever possible. GatorTrak 4-wheel steer maintains rear wheels in front wheel paths, reducing compaction in end rows and headlands.

Minimizes Crop Damage: A tight 16 ft. turning radius means far fewer rows are crossed and compaction is reduced, significantly reducing crop damage and enhancing yields.

Save Time and Improve ROI: For those without headlands, a standard 2-wheel steer machine may require a three-point turn after each pass. If each turn takes an average of 18 seconds, and an average field is 80 acres, with GatorTrak 4-wheel steering you could cover an additional 100 acres per day or 4,500 acres per year.

Save Time and Improve ROI: For those without headlands, a standard 2-wheel steer machine may require a three-point turn after each pass. If each turn takes an average of 18 seconds, and an average field is 80 acres, with GatorTrak 4-wheel steering you could cover an additional 100 acres per day or 4,500 acres per year.

Protechi

Your operation’s competitive advantage

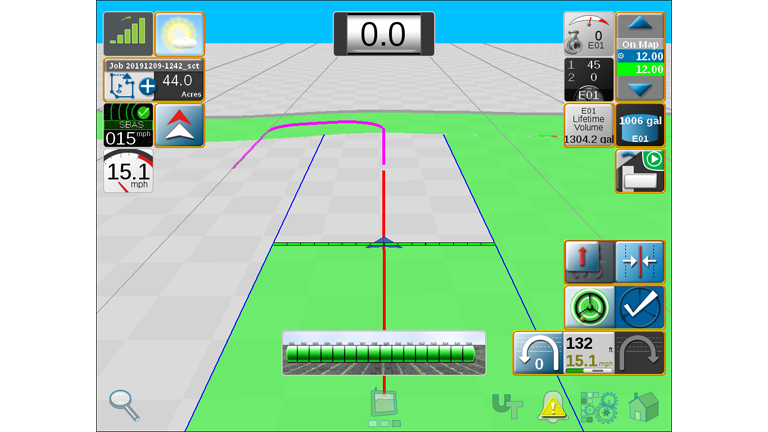

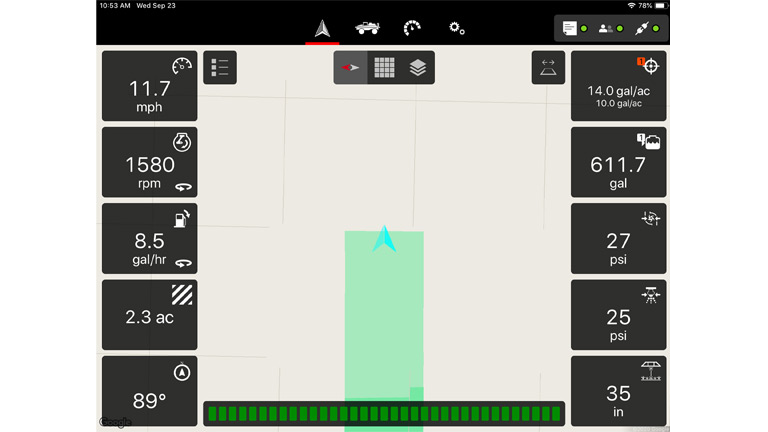

Find the latest technology inside every RoGator®. The intuitive, fully integrated AccuTerminal® gives you full machine control—from the chassis and steering to data management and system functionality—all while decluttering your space with a single screen.

- AgControl®: While ensuring highly accurate rate control and quickly achieving rate, manage up to five products via straight rate or Rx maps and create coverage maps, as-applied maps and task reports for fast and easy document reporting.

- E-Stop Nozzle Control: Regulate 36 sections with instant on-off control via small ball valves at each nozzle.

- RoGator Guide System: Integrated into the AccuTerminal for easy one-terminal control, and providing a comprehensive guidance system with waylines such as:

- AB or A+ heading

- Contour

- Pivot

- Contour segments

- Adaptive curve

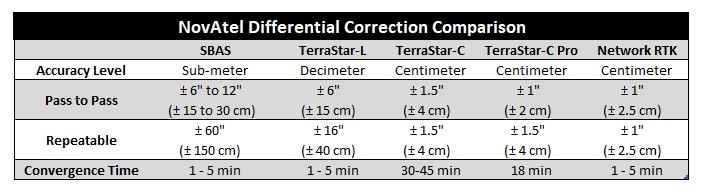

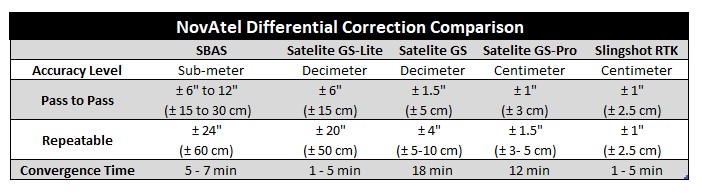

Standard NovAtel 7 Receiver

A rugged, self-contained GNSS receiver and antenna with GPS and SBAS support. Base GPS option is SBAS but can be upgraded for higher accuracy levels.

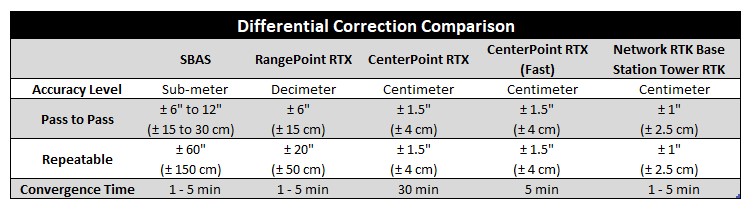

Optional Trimble AG-482 Solution

A high-performance, dual-frequency GPS and GLONASS smart antenna receiver for very high levels of accuracy and performance. Base correction source is SBAS but can be upgraded for higher accuracy levels. (Show Trible chart)

TaskDoc® Wireless Data Transfer: Manage your application data as it records as-applied data, weather data and field data including boundaries, waylines, and obstacles.

Weather Station Data: View the latest weather information and record data as a snapshot in time or throughout the field and use it for documentation of the application.

Protech+

Take your technology to the next level

If you’re looking for the ultimate in cab and machine technology, look no further than the ProTech+ package.

Viper® 4+: Offering the ultimate combination of operating power and program capabilities:

- 10-product variable rate application (VRA)

- Real-time data mapping

- Record keeping

- Intuitive touchscreen control

- High quality graphics

- Raven AccuBoom™

- Previous coverage application zones

Raven Product Control Node: CAN-based product controller, providing 16 section control from the factory regardless of boom width. Upgrading through parts to the rate control module (RCM) provides 36-section control for a cost effective way to add sections for even better control in areas with ample point rows.

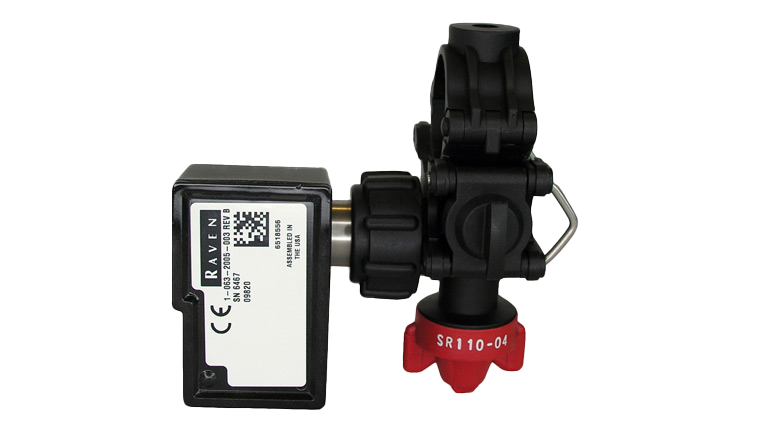

Hawkeye Nozzle Control System

Pressure-based system for precise application available through parts. Each nozzle is controlled by an individual pulsing valve to give a consistent spray pattern as speed and conditions change.

- Extended speed range from nozzle tips maintain consistent droplet size and spray pattern for maximized field speeds.

- Nozzle-by-nozzle turn compensation adjusts duty cycle to minimize over- and under-applications

- Multiple pressure settings allow for application pre-planning with lower pressure for sensitive areas and normal pressures for field interiors.

- The base package provides 16-section control regardless of boom width. The optional HD unlock increases OptiPulse accuracy with individual nozzle controls. Hawkeye HD

- Individual valve diagnostics

RS1 Guidance Technology

Fully scalable steering solution that combines Slingshot, GPS and auto steer into one intuitive, easy-to-use unit with incredible accuracy at both high and low speeds

Leverages a non-contact stereo vision camera to navigate crop rows, allowing you to focus on all other aspects of effective application control. The system helps to minimize crop damage, cover more acres in less time and provide easier machine operations. (VSN Comparison Chart)

- Requires in-field calibration, only for different crop widths.

- Three control modes for accurate steering include:

- GPS/GNSS Mode—uses traditional guidance lines.

- VSN Mode—Will only use the VSN camera.

- VSN+ Mode—Will fall back to GPS last pass if it cannot detect the crop row due to weed pressure or drown out.

VSN Full Canopy

When crops are too tall to effectively see the row, the Raven VSN Full Canopy solution compliments the VSN system with a non-contact radar sensor that detects stalked crops, such as corn, to keep the machine in between rows. Available through AGCO Parts.

- Mounted to the bottom of each front wheel leg and can detect rows when crops are too tall for the standard Fendt Vision system to identify the crop row.

- Detects multiple rows to keep the machine on track, even with row skips. Permits application speeds of up to 20 mph with a minimum row spacing of 30 in.

Raven AutoTurn

Included with the purchase of VSN, automatically performs headland turns without the operator’s input, allowing them to prepare for the next pass.

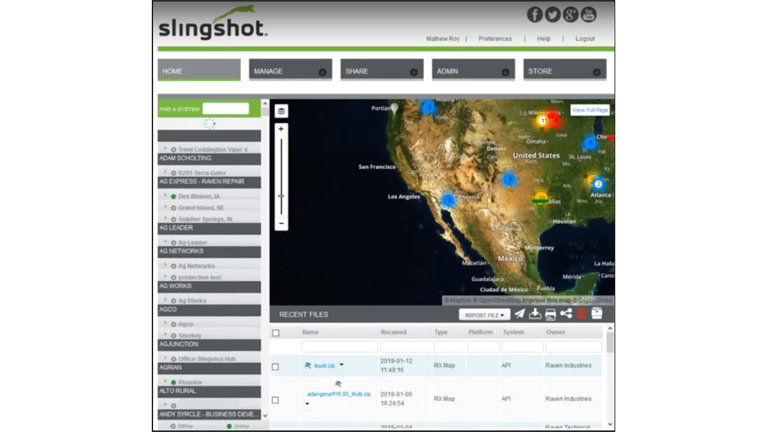

Slingshot

Suite of connected hardware, software and logistical services that optimize planning, executing and recording field applications. This system delivers high levels of connectivity to RTK correction signals, online services, sophisticated data management capabilities and live in-field support and service.

- Enables remote software updates and management capabilities.

- Send VRA maps to and from the field making office work more efficient and eliminating costly down time caused by file problems.

- Allows remote support to see exactly what the operator sees, making issue identification much more efficient and accurate.

- Includes 1-year free Silver subscription.

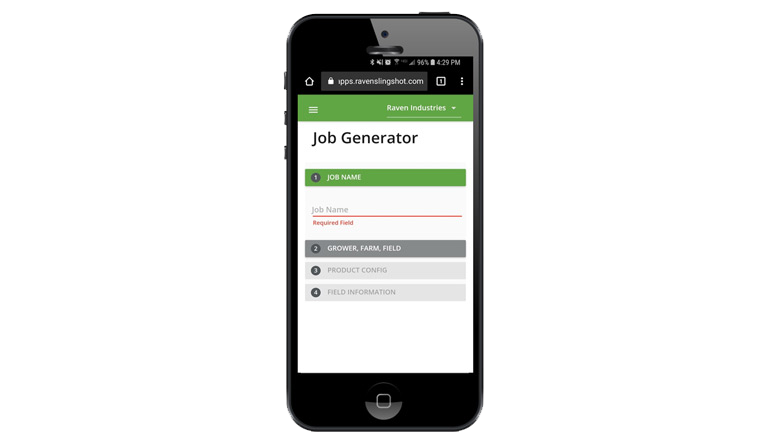

Job Generator

Fast and simple way to set up nearly all parameters of an operation ahead of time and send it out to the machine.

Job Sync

Harnesses Slingshot to allow multiple machines to collaborate on a job simultaneously or days apart—a powerful tool that practically eliminates the potential for overlap or misapplication between multiple machines in the same field.

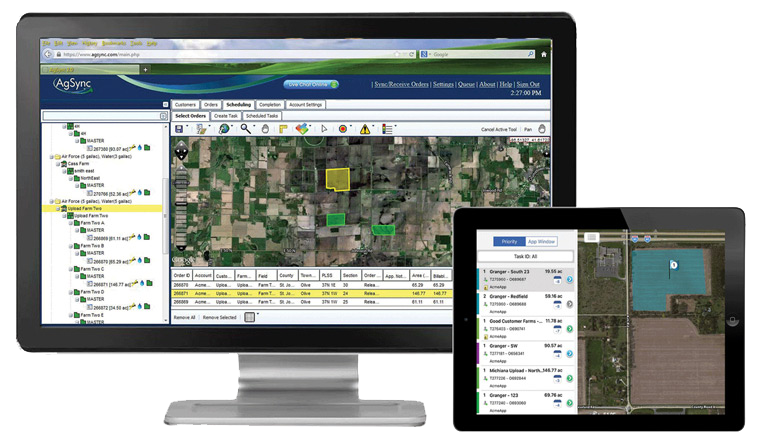

AgSync Ground

Flexible and scalable tool that leverages Slingshot’s data transfer power to streamline otherwise complex tasks, such as work order management, dispatch and asset control, reports and notifications, and filing data management.

Weather Station Data: View the latest weather information and record data as a snapshot in time to use it for documentation of the application.

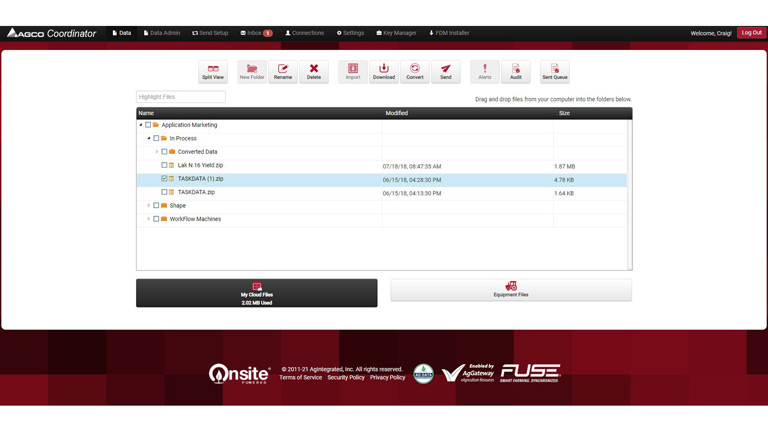

Agrolink

Data management done right

Agro Link relieves you of the data management burden by collecting, integrating and storing agronomic files—so you can focus on more important tasks.

- Save time and effort by consolidating current and historic agronomic data into a single location and file type, easily converting ISO XML files to shapefiles or vice versa.

- Simplify data sharing with trusted advisors to help your operations run more efficiently.

- Move data between cloud storage, equipment telematics and your FMIS. IMG AgroLink

- Securely store and transfer data in one unified file type on your computer or mobile device.

- API-connected partners give AgroLink flexibility to collaborate with independent systems; partners include: MyJohnDeere, Case AFS Connect, New Holland PLM Connect, Ag Leader AgFiniti, Raven Slingshot, AgBridge, Climate Fieldview, Farmmobile, Beck’s Farm Server, and more.

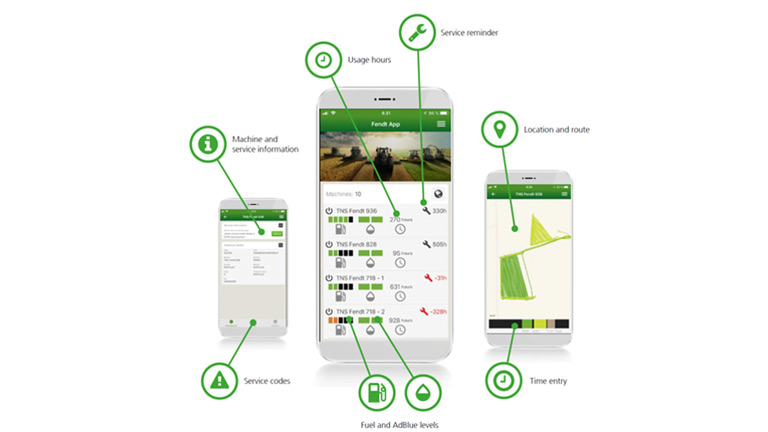

Telemetry

Connected performance perfected

Take the guesswork out of machine optimization with AGCO Connect. Track individual and fleet performance and know where, how and when you can make the most of your machines.

- Proactive service scheduling improves uptime and machine servicing through remote-monitoring capabilities.

- Improves dealer support efficiency and reduces downtime.

- Easily track key operational data, such as machine information, coverage maps and data visualization with the SmartConnect TM app on any compatible smart device.

- Premium dashboard includes a histogram that provides a live 60-minute review of critical machine data.

768x432.png)

- A customizable widget can be set up to suit the operator’s needs with up to four screen layouts.

- The AGCO connectivity module (ACM) includes a five-year subscription.

SPECIFICATIONS

|

|||

ENGINE HP @ 2100 RPM (KW) |

280 (209) |

315 (235) |

339 (253) |

ROAD SPEED MAX |

33 MPH, 53 KPH |

33 MPH, 53 KPH |

36 MPH, 58 KPH |

SV MAX GPM |

186 |

186 |

186 |

HV MAX GPM |

N/A |

299 |

299 |

BOOMS |

90/100/120 (27.4/30.5/36.6) STEEL 132 (40.2) ALUMINUM |

90/100/120 (27.4/30.5/36.6) STEEL 132 (40.2) ALUMINUM |

90/100/120 (27.4/30.5/36.6) STEEL 132 (40.2) ALUMINUM |

LIQUIDLOGIC SYSTEM |

FLOWLOGIC™ LIQUID RECIRCULATION PLUMBING NOZZLELOGIC™ AT-NOZZLE SHUT-OFF, OPTILOAD™ RELOAD STATION W/ KEYPAD, OPTIMOTION™ AUTO-SCALED AGITATION, CLEARFLOW™ BOOM CLEAN OUT/RECOVERY |

FLOWLOGIC™ LIQUID RECIRCULATION PLUMBING NOZZLELOGIC™ AT-NOZZLE SHUT-OFF, OPTILOAD™ RELOAD STATION W/ KEYPAD, OPTIMOTION™ AUTO-SCALED AGITATION, CLEARFLOW™ BOOM CLEAN OUT/RECOVERY |

FLOWLOGIC™ LIQUID RECIRCULATION PLUMBING NOZZLELOGIC™ AT-NOZZLE SHUT-OFF, OPTILOAD™ RELOAD STATION W/ KEYPAD, OPTIMOTION™ AUTO-SCALED AGITATION, CLEARFLOW™ BOOM CLEAN OUT/RECOVERY |

PNEUMATIC SYSTEM |

N/A |

AIRMAX PRECISION R1 - SINGLE BIN - 235 CU. FT. |

AIRMAX PRECISION R1 - SINGLE BIN - 235 CU. FT. |

PNEUMATIC SPREAD WIDTH |

N/A |

70 FT. |

70 FT. |

SPINNER SYSTEMS |

NEW LEADER ® G5 SPINNER AS MULTAPPLIER READY OR MULTAPPLIER COMPLETE |

NEW LEADER ® G5 SPINNER AS MULTAPPLIER READY OR MULTAPPLIER COMPLETE |

NEW LEADER ® G5 SPINNER AS MULTAPPLIER READY OR MULTAPPLIER COMPLETE |

SPINNER CAPACITIES |

258 CU. FT. |

258 CU. FT. OR 300 CU. FT. |

258 CU. FT. OR 300 CU. FT. |